end wall flashing roof

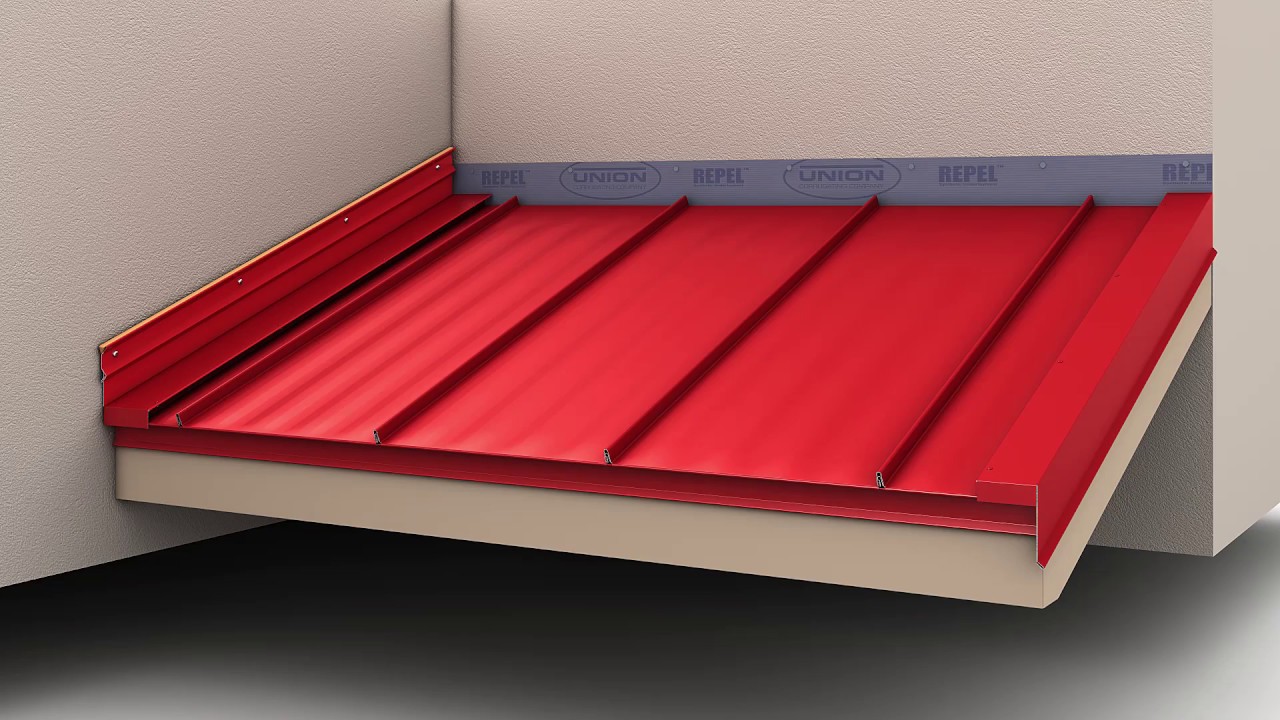

This video shows how to install Endwall Flashing with standing seam panels. The metal flashing is formed with a hook edge and cleated on 12 centers.

This color matched flashing also provides a professional finishing touch to your roof.

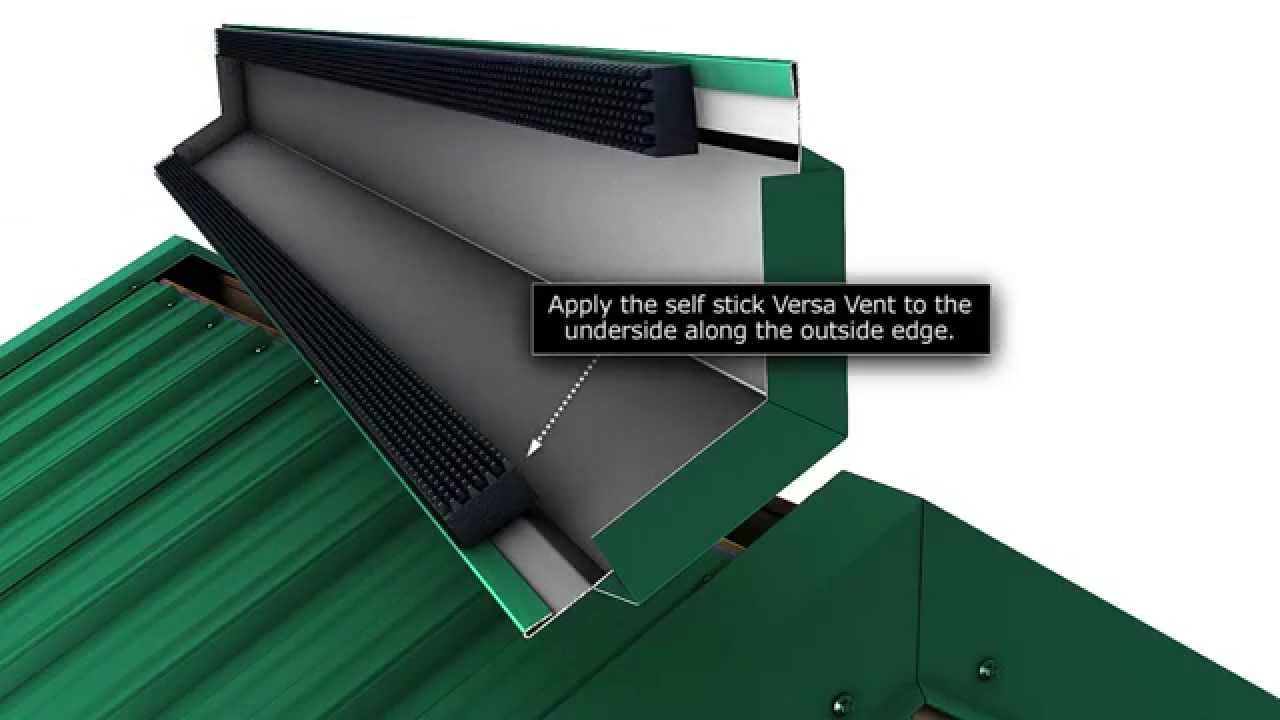

. Its placed behind the wall steel and on. Expert Technical Support Specialist on Hand to Answer Your Call 6 Days a Week. The wall side of the flashing can be covered with siding or counter-flashing and outside closures are necessary to seal between the flashing and the panel.

At roof-to-wall intersections see Figure 1. Stramit Roof and Wall Flashing is generally manufactured from G300 steel with protective coatings of ZINCALUME galvanised or COLORBOND. Ad Roofing Concrete Repair Supplies And Many Other Products At Affordable Prices.

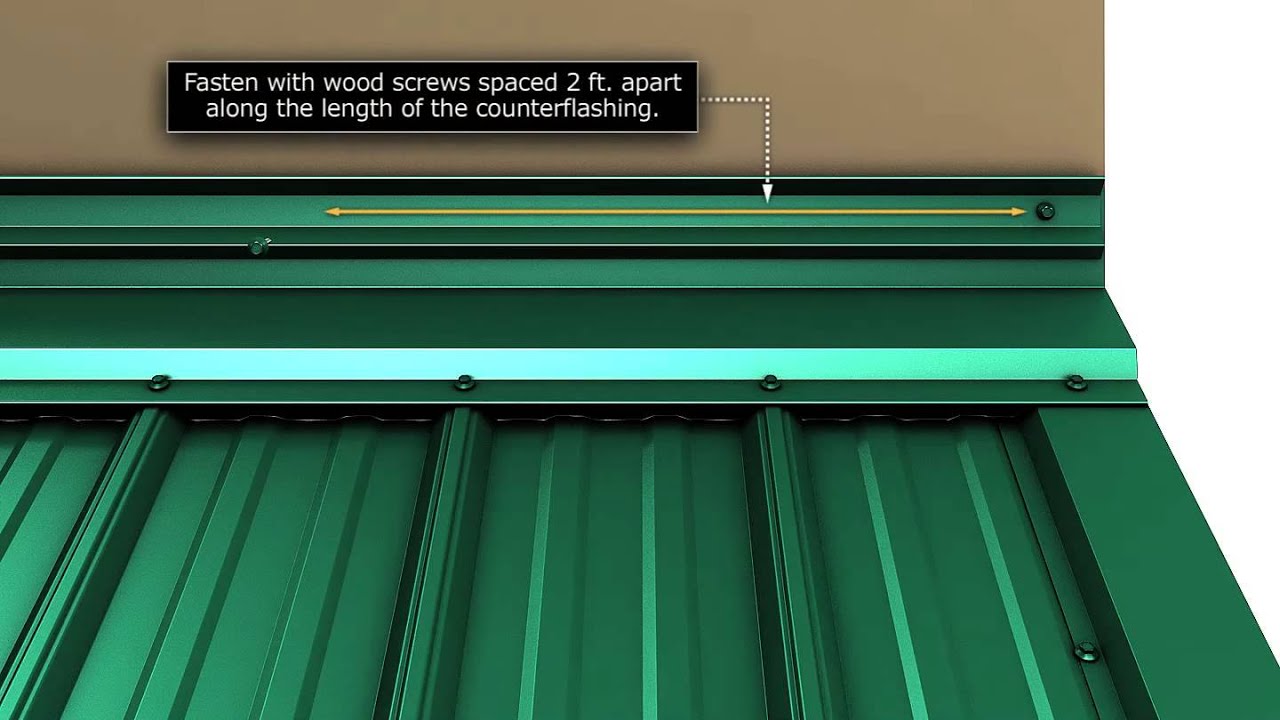

Attach endwall flashing to roofing panels using 9 x 2 woodgrip fasteners 9 on-center every rib to prevent dimpling of endwall flashing. Do not seal housewrap or building paper to step flashing. Install outside closures where the flat of the endwall flashing will be fastened to the roofing panels.

Roof flashing is a thin material usually galvanized steel that professional roofers use to direct water away from critical areas of the roof wherever the roof plane meets a vertical surface like a wall or a dormer. ADD UP THE TOTAL LINEAR FEET OF ENDWALL NEEDED AND DIVIDE BY 95 Click the link below to see an installation guide for Endwall Flashing. The flashing extends onto the roof a minimum of 2 inches - 4 inches is preferable in more severe climate areas.

Step By Step Endwall Flashing Installation Instructions On A Metal Roof. End-wall flashing is applied where the upward slope of a roof meets a wall. Endwall Flashing Installation Steps.

Tape the top of step flashing with 4-inch-wide minimum self-adhering modified bitumen roof tape. Where flashing is metal the metal shall be corrosion resistant with a thickness if not less than 0019 inch 26-gauge galvanized sheet 2018 IRC R90321. The purpose of endwall trim is to help control the flow of water which will protect your structure.

Other materials such as COLORBOND Ultra COLORBOND Stainless Uncoated Stainless Copper and Aluminium are also available. Install Metal Roof Endwall Trim At The Sidewall. Get Quick Low-Cost Shipping Anywhere Today.

10 Long Length 26 Gauge Metal Matches color of panel Use with OUTSIDE CLOSURES HOW MANY DO I NEED. Fasten the folded sides of the gable with stitch screws. Step by step guide that will show you how to install endwall flashing for a metal roof.

The flashing extends up the wall at least 4. You can also use pop rivets to fasten the flashing. Roof to wall flashing is critical to the performance of every single-ply roofing system.

Cutting and finishing endwall trim at the sidewall foam closure installation plus how to overlap and fasten the endwall flashing. The End Wall Flashing provides protection where a roof intersects with a vertical wall. Roof-To-Wall flashing is bent at a 110.

Flashing is installed to surround roof. The shorter vertical plane is attached to the upper floor wall under the building paper the lower plane sits on top of the underlayment and under the shingles. Roofing End Flashing 50MMX24X8FT.

These transition points where the flat part of the roofing system is tied into the parapet wall are potentially vulnerable areas for water intrusion. Colours Stramit Roof and Wall Flashing is available in a. It can be installed with or without a reglet trim.

Ad QF Ducting Is Available In Galvanized Stainless Steel In Diameters From 3 -24 Inches. Installation Instructions For Endwa. By Karen L Edwards 08-06-2021.

Its located on the upward slope of the roof and is bent to the same pitch. Flashing is required at roof-wall intersections step flashing and to divert water away from where the eave of a sloped roof intersects a vertical sidewall kick-out flashing. Great For Facilities Of All Sizes From Large Manufacturing Plants To One-Person Shops.

Used in conjunction with closure strips or butyl tape it reliably protects against water infiltration. Endwall flashing is installed on a vertical wall and then fastens to the top of the metal roofing panel. Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall.

It is designed to cover and protect roof-to-wall intersections from water infiltration. The video features Unions Advantage-Lok II standing seam roofing panel which is. Gibraltar End Wall Flashing can be used with most metal roofing profiles.

Use step flashing that has a 2- to 4-inch-longer vertical leg than normal. This article even includes a video and will cover. Endwall Flashing Installation Place the flashing on top of the Z-trim making sure that the flashing is up against the wall.

Following the requirements for proper flashing can help ensure that the roof system offers. The Gibraltar Roof-To-Wall Flashing is made from trusted 28-Gauge galvanized steel. End-wall flashing is applied where the upward slope of a roof meets a wall.

Installing Drip Edge Details Roof Cost Estimator Calculate Your Roof Replacement Costs Standing Seam Metal Roof Metal Roof Standing Seam

Pitched Roof To Brick Wall Huse

Pin By End Studio On Porch Ideas Masonry Wall Shingling Roof Maintenance

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Roof Truss Design

How To Install Standing Seam Metal Roofing Hip Cap Youtube Metal Roof Roofing Metal Roof Installation

Union Corrugating Provides How To Install Metal Roofing Videos For Masterrib Panels And Advantage Lok Ii St Metal Roof Metal Roof Vents Metal Roof Installation